In the Spring of 2016, DBR was hired to perform retro-commissioning for a public school district in Texas. The project was a 396,000 sf high school that was constructed in 2001-2002. The scope was limited to the HVAC system and associated controls. The process lasted for five months and included functional testing over a six week period which identified 155 issues in 17 categories. The estimated energy savings that could be realized by implementing the identified energy conservation measures was 41%.

The Process

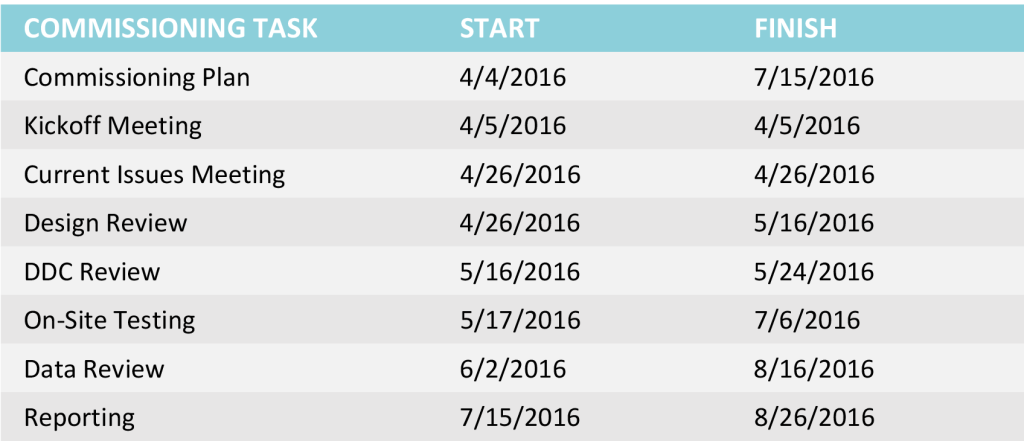

Retro-commissioning is the process of performing commissioning on an existing building that has never been commissioned. For this project, the process began with meetings with the maintenance staff and energy management staff to understand the current status of operations and maintenance of the facility. Next, the current sequences of operation for the different systems were documented. Once the facility operations and system sequences were understood, an OPR (Owner’s Project Requirements) was constructed to guide the commissioning process. A series of functional test procedures were developed, based on the specific types of equipment and the new sequences of operation. After the functional tests were ready, the systems were methodically tested, with the cooperation of the facilities staff including HVAC maintenance personnel and a controls technician, to document the operation and identify any deficiencies or “issues”, and to uncover opportunities for potential energy savings. Following the testing, a list of the deficiencies identified, recommended energy conservation measures, and a report of the entire process were prepared. The table below lists the tasks accomplished.

The Project

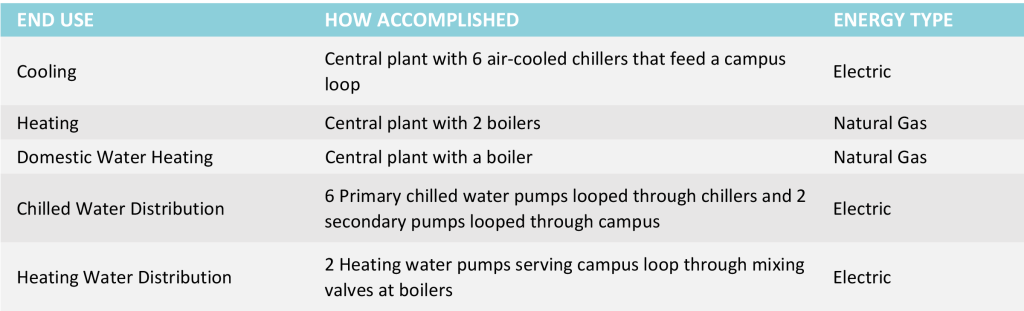

This project was a 396,000 sf high school with an air-cooled chilled water plant and hot water heating. The scope of the retro-commissioning effort included the HVAC systems and associated controls. The entire process occurred over a five-month period that included a meeting/coordination phase where the team was introduced and schedules were developed, a testing phase over the period of six weeks, and a reporting phase to review and fine-tune the report to meet the district’s informational needs. The testing phase began with a comprehensive review of the existing HVAC systems and the DDC control system. Once the status of the existing systems was understood, a plan was developed to test the equipment. Field testing of the equipment was performed to observe the actual operation. Finally, the results of the testing were used to develop lists of potential energy conservation measures (ECMs) and maintenance issues which required correction.

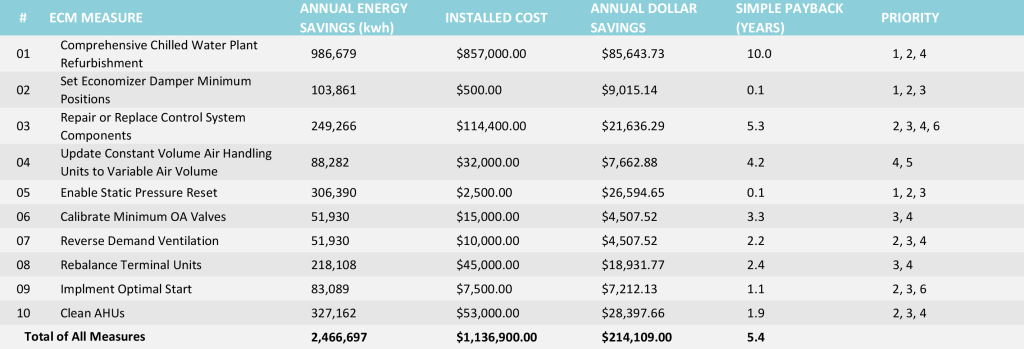

Energy Conservation Measures & Analysis

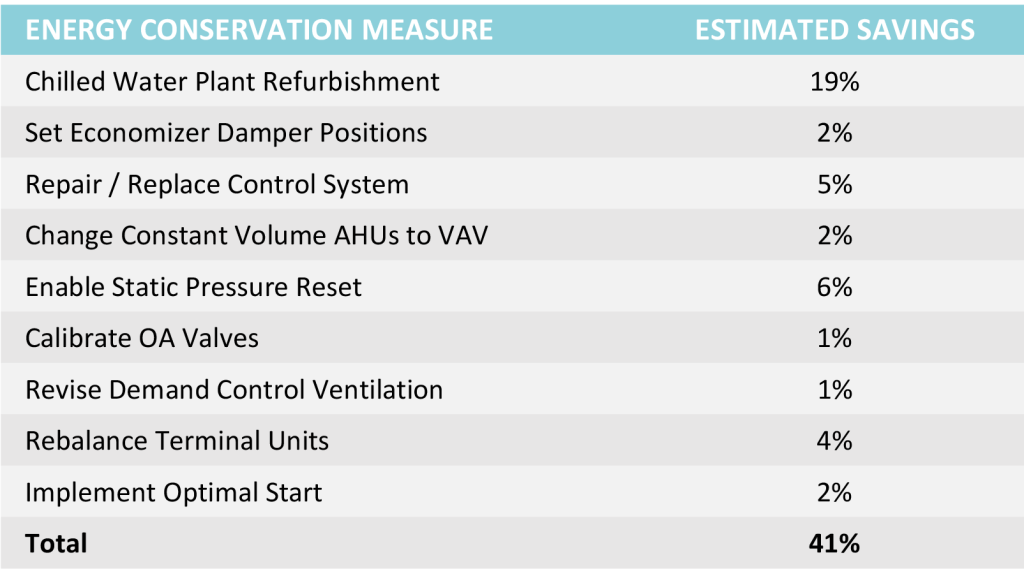

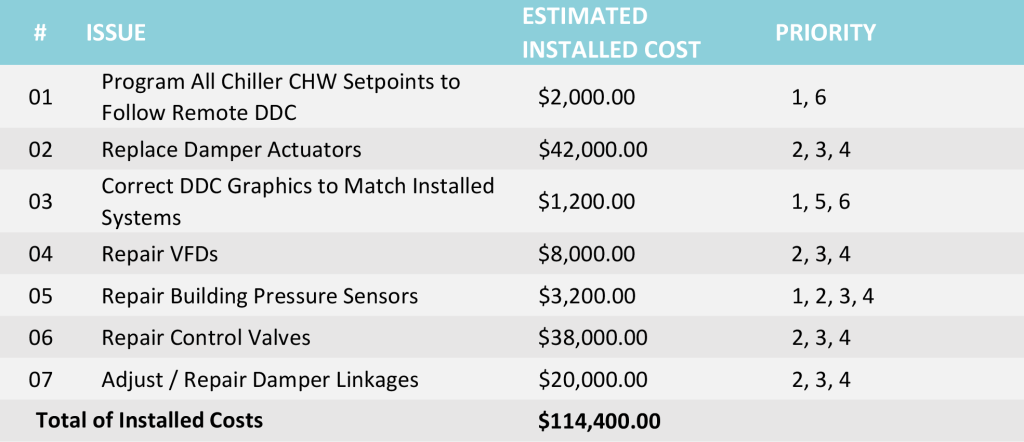

The retro-commissioning process, including the drawing review, control review, and functional testing, identified 155 issues. These issues were categorized under one of two headings for the purposes of the project: Energy Conservation Measures and Maintenance Issues. Since the proper and efficient operation of a building control system is the first and foremost energy conservation measure, the process identified faulty components of the system and categorized them as maintenance issues. The maintenance issues were discovered while conducting functional testing and are typically such things as faulty damper actuators, incomplete or incorrect graphics, and control valve actuators. The maintenance issues are usually addressable by the Maintenance department and are necessary for the building control system to function properly. During the process of testing, control system review and drawing review, the opportunities that are discovered to make changes that could reduce the energy consumption of the facility or otherwise improve the performance of the systems are deemed the “Energy Conservation Measures”. These ECMs are typically operational in nature but can also overlap into the maintenance category.

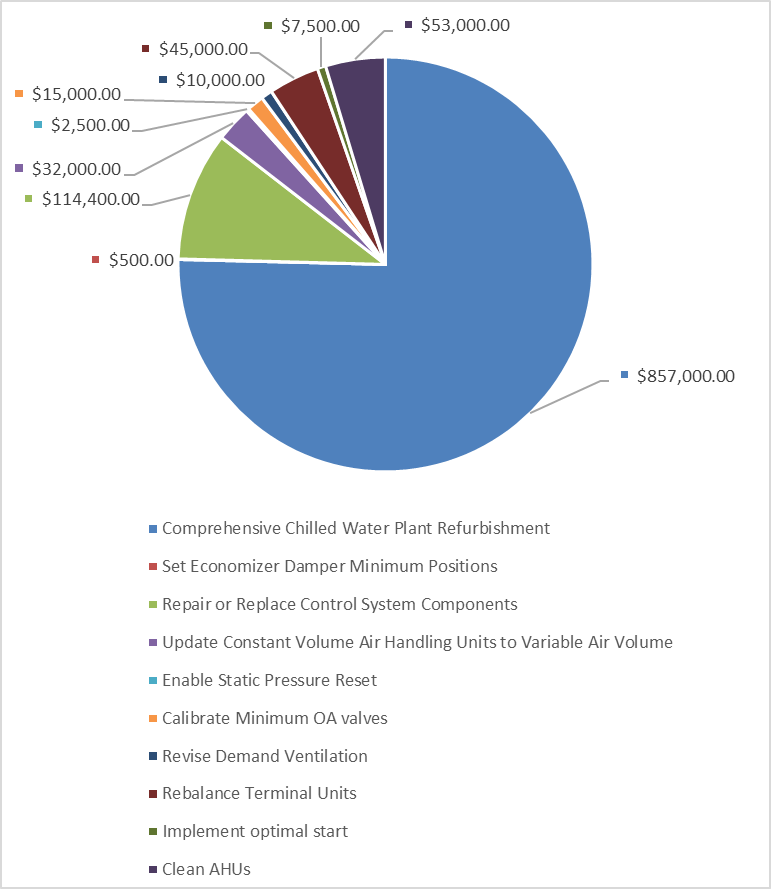

In order to assist the school district with their decision making about the implementation of our recommendations, we provided estimated costs for the implementation of each recommendation along with the projected cost savings. The actual savings will depend on many factors including which measures are implemented, seasonal weather variations, energy prices and specific operation of the facility.

* Costs shown are to assist in prioritizing and comparing the extent of capital expenditure. Actual budgets should be determined by detailed examination of the issues. Cost savings are based on 8.68 cents per KWH.

Priority:

1. Should be addressed immediately

2. Operation/maintenance measure

3. Should be addressed within 5 years

4. Capital investment measure

5. Optional

6. Operational measure that will assist energy manager in identifying excessive use and potential savings

* Costs shown are to assist in prioritizing and comparing the extent of capital expenditure. Actual budgets should be determined by detailed examination of each issue.

Priority:

1. Should be addressed immediately with minimal cost

2. Operation/maintenance measure

3. Should be addressed within 5 years

4. Capital investment measure

5. Optional

6. Operational measure that will assist energy manager in identifying excessive use and potential savings

Conclusion

The retro-commissioning process identified many opportunities to improve the operation of the school’s HVAC systems and to reduce operating costs through energy conservation. The DBR commissioning team was able to provide recommendations to address the mechanical equipment issues and recommendations to improve operations. Although this facility was only 15 years old and had been fairly well maintained, we still found issues that need to be addressed and some opportunities to significantly reduce energy costs.